How to Calculate the Flow Rate of a Pump

Calculating a pump’s flow rate is the key to ensuring the right amount of fluid is delivered to the right place at the right time. In this guide, discover the formulas, considerations, and expert tips to make your flow rate calculations a breeze.

Key Components Affecting Flow Rate

Flow rate, often measured in terms of volume or mass per unit time, is a critical parameter in industrial processes. It measures the speed at which fluids move through pipelines, valves, and other system components. Controlling and maintaining an optimal flow rate is essential for process stability, product quality, and energy efficiency.

Below are some key components affecting flow rate:

Piping Design and Dimensions

- Pipe Diameter: A larger diameter allows for a higher flow rate, reducing pressure drop and fluid resistance.

- Pipe Length: Longer pipes increase the resistance and reduce the flow rate, necessitating more powerful pumps.

- Pipe Material: Roughness and corrosion resistance of the pipe material can impact the flow rate by altering internal friction.

Valve Types and Settings

- Valve Design: Different designs (ball, gate, globe) have varying impacts on flow rate.

- Valve Position: The degree to which a valve is opened or closed directly affects the flow rate.

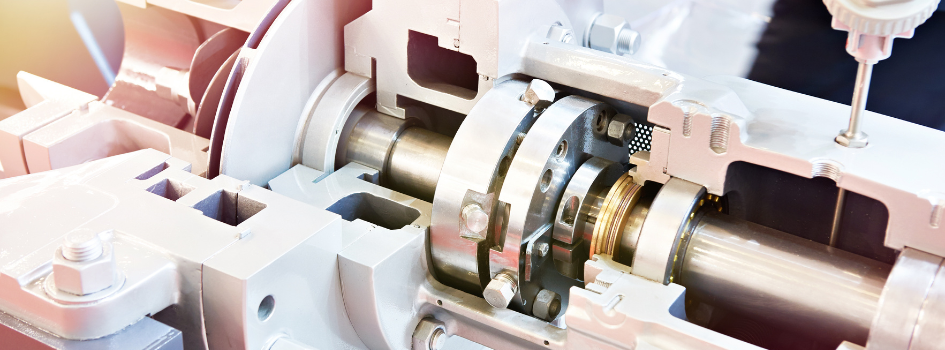

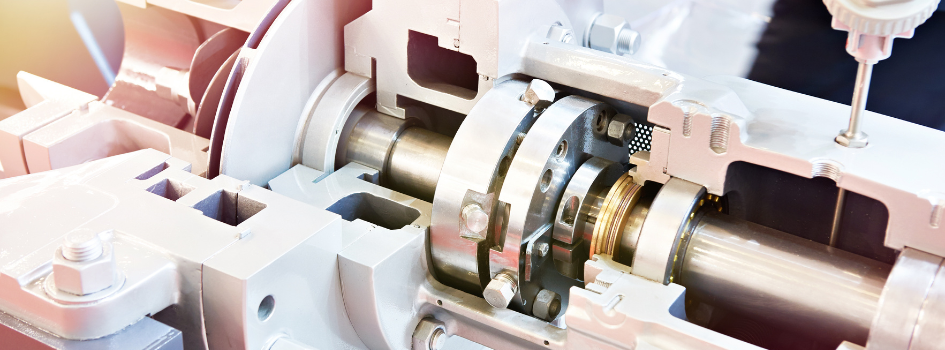

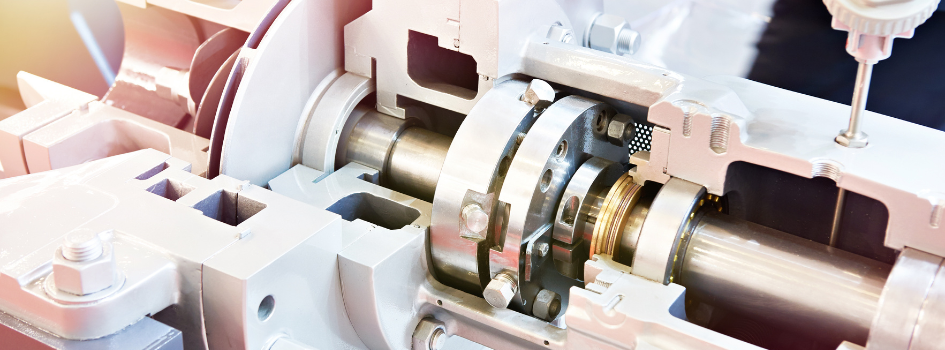

Pump Performance and Characteristics

- Pump Type: Centrifugal, positive displacement, and diaphragm pumps have different impacts on flow rate.

- Pump Capacity: The design and operational capacity of a pump can influence the pump flow rate.

Fluid Properties

- Viscosity: Higher viscosity fluids move slower, affecting the flow rate.

- Density: The density of the fluid can impact pump selection and flow rate.

- Temperature: Changes in temperature can alter the viscosity and, subsequently, flow rates.

System Pressure and Gradients

- Pressure Differential: The difference in pressure between two points in a system drives the flow.

- Elevation Changes: Gravitational effects due to elevation changes in the system can impact flow rates.

Filters and Strainers

- Clogging: Accumulation of debris in filters reduces flow rate.

- Filter Type: The design and pore size of filters influence the flow rate.

Pump Flow Rate Calculation Formula

The pump flow rate calculation is an essential aspect of many engineering projects. Accurate calculations ensure the efficiency, reliability, and effectiveness of your systems — from simple water pumps to complex industrial processes.

The basic formula to calculate the pump flow rate is:

Flow Rate (Q) = Area (A) × Velocity (V)

- Q is the flow rate

- A is the cross-sectional area of the pipe or channel

- V is the velocity of the fluid

This formula is the foundation for more complex calculations and adjustments that may be needed based on specific application requirements and fluid characteristics.

Practical applications in system design include:

- System Capacity Planning: Engineers must calculate the required flow rate to meet system demands, such as HVAC systems or water supply networks.

- Selection of Pump and Components: Accurate flow rate calculation is crucial for selecting the right pump and sizing the piping and other components.

- Energy Efficiency Optimization: By understanding flow rates, engineers can optimize systems for energy efficiency, reducing operational costs.

- Troubleshooting and Maintenance: Regular flow rate checks can help in the early detection of issues like pipe blockages or pump wear.

Tips for Accurate Calculations

Accurately calculating pump flow rates is crucial in various industrial applications, from wastewater treatment to chemical processing. Ensuring pumps operate efficiently and effectively is vital for optimizing processes and preventing costly downtime and pump maintenance.

Below are some factors to consider for accuracy:

- Identify Pump Specifications: Check the pump’s data sheet for its maximum flow rate, efficiency, and operational curves.

- Determine System Requirements: Understand the required flow rate for your specific application.

- Consider Fluid Properties: Adjust calculations for the viscosity and fluid density.

- Account for Real-World Factors: Include factors like pipe friction loss, which can reduce the actual flow rate.

- UsePump Performance Curves: These curves, provided by manufacturers, show how flow rate changes with different head pressures.

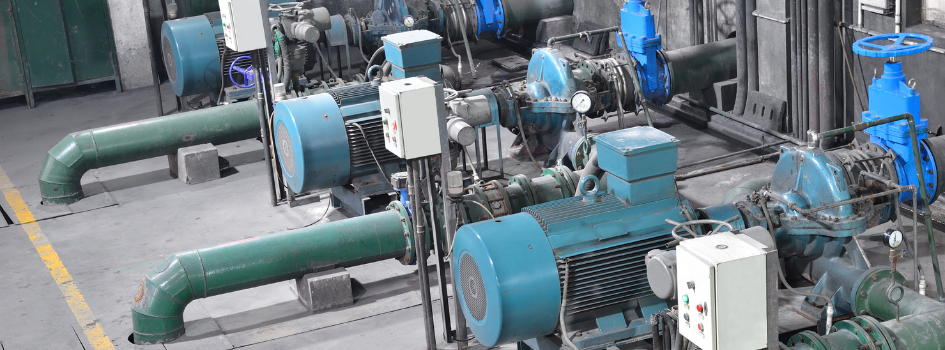

Discover IFS/DXP Advanced Pumping Solutions

IFS/DXP offers state-of-the-art pumping solutions designed to meet the diverse needs of modern industries. Our portfolio includes various industrial pumps optimized for specific applications and fluid types. With our focus on innovation, energy efficiency, and reliability, we ensure that your systems operate at peak performance, delivering the precise flow rate required for your specific operations.